2022 was another productive year in laboratories across the United States and beyond, as colleges, manufacturers, and startups strove to challenge the orthodoxy of construction materials. While teams of students and researchers at institutions from Virginia Tech to ETH Zurich sought to push the boundaries of traditional materials such as timber and concrete, disruptive startups sought to broaden this palette with the introduction of everything from recycled plastic to mushrooms.

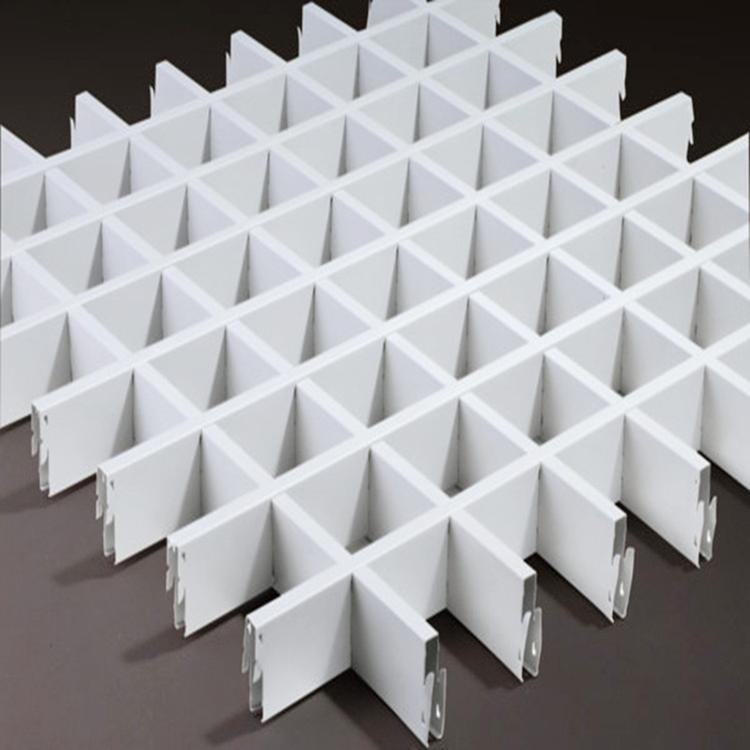

These investigations into material science were matched by equally impressive advancements in construction processes, marking 2022 as a year that asked ‘how’ we build as well as ‘what’ we build with. As with previous years, 3D printing featured heavily in 2022’s highlights of intriguing construction innovations, be it new nano-structural 3D printed systems that can sense their own movement, or a growing portfolio of real-world 3D printed homes which signal the arrival of the once-novel process as a viable market option. Suspended Ceiling Aluminum Panels

To further explore these phenomena, we have set out the key developments and stories throughout 2022 which showed the impact of material science and 3D printing on architectural thinking and, increasingly, on the built environment itself.

In April, a Virginia Tech team used low-carbon timber to construct an observation tower

The project saw the development and certification of a new custom timber product, off-site prefabrication, and the discovery of the ruins of a historic building. Measuring 75 feet long and 30 feet high, the resulting tower is the first permanent building in the world to use modular hardwood cross-laminated timber (HCLT) construction, and the first permanent HCLT building permitted in the United States.

While a geodesic dome by ETH Zurich students demonstrated the potential beauty in waste timber

By dismantling an entire floor of an old car depot scheduled for demolition, the group salvaged OSB panels, wooden beams, steel girders, and plastic piping for use in the pavilion. The team has also sought to use the project to make a broader statement about the role of material cataloging in the construction industry, specifically the use of digital material passports.

In Cairo, engineering students developed concrete that can glow in the dark

Mimicking natural processes, the concrete releases its energy at night in the form of light rays. The team is determined to use the new method to offset concrete’s poor environmental performance through applications such as illuminating roadways.

While Washington State University researchers created stronger cement by adding shrimp shells

By putting nanoparticles from shrimp shells into cement paste, the team believes that their innovation could lead to reduced seafood waste and lower carbon emissions from concrete production. The addition of shrimp nanoparticles to the mixture saw a 40% increase in the concrete’s strength and a 12% improvement in its compression load capacity.

As the year ended, a terracotta system took a lesson from history to cool water and air

Titled ‘Nave,’ the system draws references from the traditional Palestinian technique of hanging terracotta water containers from ceilings to provide drinking water and space cooling. Three variations of the system are offered: wall tiles, partitions, and totem cooling bodies, each made from local terracotta cast from plastic molds.

In January, a startup unveiled recycled plastic blocks with similar properties to concrete

ByFusion’s interlocking blocks use the same principles as LEGO with protrusions on the top surface, allowing for blocks to be pieced together to form retaining walls, sheds, privacy fencing, accent walls, landscaping, and furniture. The blocks are sized to the same dimensions as standard concrete blocks but generate 41% less greenhouse gas emissions during manufacturing.

One month later, MIT researchers created a new material as light as plastic and strong as steel

The new material centers on breakthroughs in the binding of polymers, microchemical substances composed of molecules that form the building blocks for modern artificial materials. The team hopes that the compound may one day be used as a structural material for buildings and infrastructure.

In April, the University of Virginia campus became a showground of biomaterial structures

The Biomaterial Building Exposition was organized by the university’s architecture school and showcased the possibilities of organic, bio-based materials, including salvaged lumber and fungal structures. The exhibition, and the projects featured within it, were created by a combination of UVA students, visiting scholars, and biomedical engineering researchers.

While SOM, Autodesk, and Microsoft funded a company’s development of algae masonry blocks

Prometheus Materials is using the $8 million funding to develop an algae-based, zero-carbon alternative to Portland cement. “To prevent catastrophic climate change, we cannot simply replace fossil fuels with renewable forms of energy — we must also decarbonize the way we create building materials,” the company’s founder said.

In September, a UNC Charlotte architecture professor was awarded $1 million toward incorporating algae in windows

Professor Kyoung Hee Kim believes her “biochromic windows” will offer multiple environmental, economic, and health benefits. The tint and color of the algae can respond to solar intensity and daylight to create optimal indoor conditions, while excess algae can be used to support domestic water heating or harvested and used in the development of food, fertilizer, cosmetics, and biofuels.

While in October, researchers found new ways of using fungi to decarbonize construction waste

The mushroom myceliums are being tested on the discarded asphalt roofing shingles of 214 homes. Researchers are currently combining the fungi and shingles to create a new byproduct that could be reused in the built environment.

As the year began, ETH Zurich announced a 3D printed foam to drastically improve concrete formwork efficiency

The foam elements were created using a 3D printed robotic arm before being manually placed in a conventional timber perimeter formwork. Following the concrete’s pouring and curing, the foam shapes can be used as stay-in-place applications or removed and recycled for printing in later formworks.

While MIT developed a 3D printed material that uses air pressure to warn about its own movement

The 3D printed lattice material contains networks of air-filled channels, allowing engineers to detect when bending, squeezing, or stretching of the structure causes a change in air pressure through the channels.

Montana became the first U.S. state to approve 3D printed alternatives to concrete walls

The vote by regulators came after a local contractor demonstrated the safety of a special 3D printed wall prototype with the aid of the University of Connecticut. The company behind the prototype estimates that the 3D printing method could reduce the cost of building a home by 30% compared to traditional concrete block or wood-framed houses.

While UVA researchers developed 3D printed structures made of soil and seeds

Given the environmental benefits of integrating green spaces with buildings, the researchers wanted to investigate the possibility of developing complex structures which are themselves made of natural materials. Their approach combines the speed, cost efficiency, and low energy demands of 3D printing with locally-sourced, bio-based materials.

In Stanford, engineers developed a 3D printing method that combines multiple resins

According to the researchers, the new method is five to ten times faster than the quickest high-resolution printer currently available, and is uniquely capable of using multiple types of resin in a single object. The researchers are now developing software to make the technology more accessible to designers.

While in an exciting end-of-year twist, ICON gained NASA’s backing to develop 3D printing methods for the Moon and Mars

The $57.2 million contract was awarded under NASA’s Small Business Innovation Research program and will see ICON develop “space-based construction technology” with the aim of creating humanity’s “first-ever construction on another planetary body.”

In March, ICON and Lake|Flato offered a look inside their curving 3D printed home in Austin

Named “House Zero,” the three-bedroom, 2,000-square-foot home adopts a “mid-century modernist ranch house aesthetic” while also exploring how 3D printing can enhance resilience and sustainability. The curved 3D printed walls serve as a strong design feature throughout the home, with rounded corners creating soft, natural circulation routes.

While students from IAAC 3D printed a zero-waste housing prototype using raw earth

TOVA was conceived as a prototype for sustainable housing that could be built anywhere in the world. Construction of the prototype took seven weeks to complete, using materials sourced within a 164-foot radius of the site.

At Cornell, two professors set out to construct the first multistory 3D printed structure in the U.S.

The two-story, single-family home merges 3D printed concrete with a traditional timber frame, creating what designers Leslie Lok and Sasa Zivkovic believe is a precedent for future 3D printed multifamily and mixed-use developments.

While ETH Zurich students and researchers showcased a 3D printed ‘eggshell pavilion’

The pavilion’s design and fabrication was driven by algorithms that generated both the geometry of the structure and the fabrication data needed to 3D print the pavilion. The team believes that this combination of computational design and robotic fabrication can unlock the potential for designers to shape concrete elements more efficiently.

In November, BIG and ICON began construction on a community of 100 3D printed homes in Texas

The 100-home Wolf Ranch development is being constructed in the city of Georgetown, just north of Austin. The interior material palette includes printed wall textures and polished concrete floors, while the homes' exteriors will be chosen from 24 elevation styles

While the University of Maine celebrated the completion of the world’s first 100% bio-based 3D printed home

Titled BioHome3D, the single-family project was printed offsite in four modules before being transported to its current location and assembled in half a day. The fully-recyclable structure is currently situated on the university campus, equipped with sensors for thermal, environmental, and structural monitoring to test how the home performs throughout the winter.

Are you sure you want to block this user and hide all related comments throughout the site?

View all | Firms

Ringlock Scaffolding View all | Schools